34

RUSSIA - FRANCE

C

ould you briefly describe the

activity of the terminal?

The Dunkirk LNG terminal is an

industrial site designed to supply to

its customers services for the stora-

ge and regasification of liquefied

natural gas (LNG) before it is injected

into the transport network according

to customer needs. LNG is natural

gas that is cooled to a temperature of

around minus 162 degrees Celsius to

make it liquid. Its volume is then six

hundred times smaller than in its

gaseous form, which makes it possi-

ble to transport it by ship from pro-

duction areas that are far from

consumption areas. The Dunkirk

LNG terminal has annual regasifica-

tion capacity of thirteen billion cubic

metres of gas, i.e. approximately

twenty percent of French and Belgian

consumption. Our terminal is also

the only one that is directly connec-

ted to two markets, the French and

Belgian ones. This enables Dunkirk

LNG customers to supply the

German market through Belgium.

Germany is currently facing a

gradual fall in its gas supplies.

How was this project developed?

It was the encounter of three major

industrial companies, EDF, Fluxys

and Total, which enabled the project

to develop. With more than thirty-five

years of expertise in LNG, Fluxys, a

Belgian energy operator, is actively

contributing to the development

of an integrated European transport

network that facilitates the circulation

and trading of natural gas. Gaz-

Opale, a fifty-one percent subsidiary

of Dunkirk LNG and a forty-nine

percent subsidiary of Fluxys, is the

operator of the facility. Among Gaz-

Opale’s fifty-eight staff members,

there are some that are seconded

from Fluxys, which is an expert in this

field due to its experience on the

Zeebrugge LNG terminal.

What are the technical features of this

industrial site?

From a technical point of view, the

Dunkirk LNG terminal has one of the

largest storage capacities in Europe

with its three LNG tanks, each of

which has a capacity of two hundred

thousand cubic metres. The site is

located on a fifty-six hectare platform

in the Port of Dunkirk and provides a

new seafront for the arrival of LNG in

France. It is equipped with a jetty that

enables the unloading and reloading

of the largest LNG carriers, which

have a capacity of two hundred and

sixty-seven thousand cubic metres

and which are known as Q-max

carriers.

Ten regasification units reheat the

LNG and transform it into natural gas

before it is sent through the transport

network. Thanks to a five-kilometre

submarine tunnel that links the

Gravelines nuclear power station and

the Dunkirk LNG terminal, five

percent of the warm water that is

discharged by the power station is

recovered to heat the LNG to trans-

form it into gas. This industrial

synergy leads to savings that are

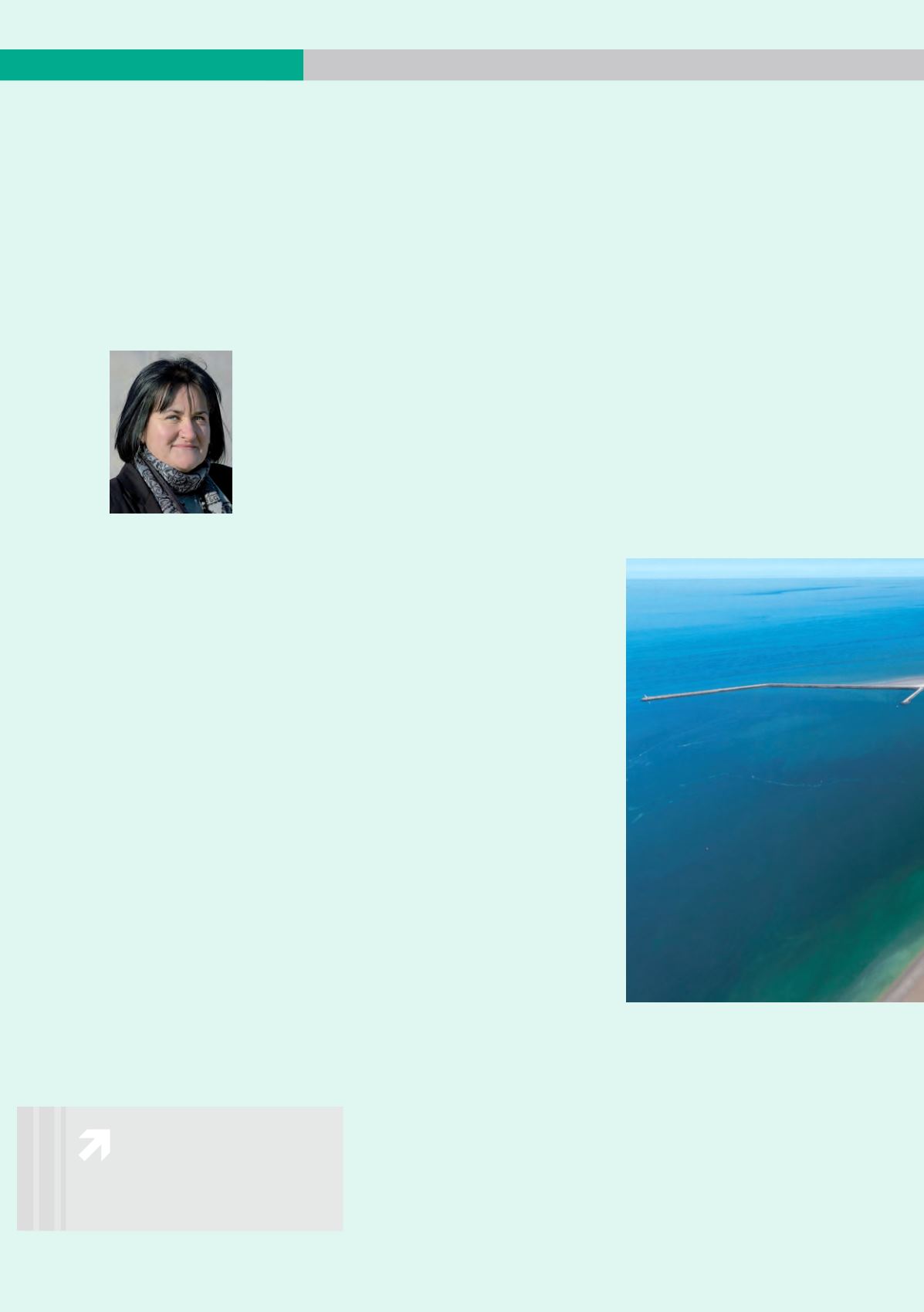

The Dunkirk LNG terminal is located at the crossroads of the sea routes between

the Channel and the North Sea and close to the natural gas consumption markets

in North-West Europe. It is a real competitive tool and bolsters the security of natural

gas supply for France and Europe.

Béatrice PRUD’HOMME,

CEO of Dunkerque LNG

©DR

‘The Dunkirk LNG terminal

has one of

the largest storage

capacities in Europe’

• 5 years of construction

• 7,200 people worked on the

building site

• 11 million hours worked

• 1.2 billion euros invested

• Up to 170 LNG carriers a year